Application

Type RHH or RHW-2 or USE-2 conductors are used with conduit as specified in the National Electrical Code. When used as Type USE-2, conductors are suitable for use as underground service entrance conductors for direct burial at conductor temperatures not to exceed 90°C. When used as RHW-2 or USE-2, conductor temperatures shall not exceed 90°C in wet or dry locations. Voltage rating for RHW-2 or RHH or USE-2 conductors is 600 volts.

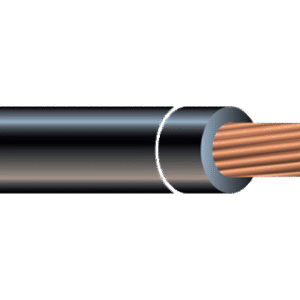

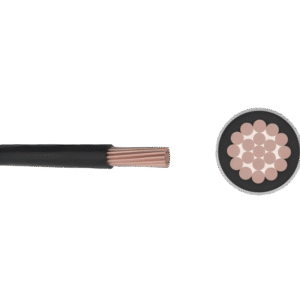

Construction

Type RHH or RHW-2 or USE-2 copper conductors are annealed (soft) copper. Insulation is an abrasion, moisture, heat, and sunlight resistant black crosslinked polyethylene (XLP). An optional CT rated product is available upon request for sizes 1/0 and larger.

Features

● Conductor for reduced diameter

● General purpose use in construction:

● Residential

● Commercial

● Institutional

● Industrial construction

Standards & References

Type RHH or RHW-2 or USE-2 conductors comply with the following:

● ASTM – B3, B8 (7, 19, 37, 61 Strands), B787 (19 Wire Combination Unilay Strand)

● UL 44 for RHH or RHW-2

● UL 854 for USE-2

● National Electrical Code, NFPA 70, 2011 Edition

● NEMA WC-70 Construction Requirements

● RoHS/Reach Compliant

Technical Parameter

| Conductor | Insulation thickness | Nominal O.D. | Approx. weight | Ampacity+ | |||||

| AWG/kcmil | Min. No. | mm | mils | mm | kg/km | 60℃ | 75℃ | 90℃ | |

| 14 | 7 | 1.14 | 45 | 4.1 | 30 | 15 | 15 | 15 | |

| 12 | 7 | 1.14 | 45 | 4.5 | 43 | 20 | 20 | 20 | |

| 10 | 7 | 1.14 | 45 | 5.2 | 64 | 30 | 30 | 30 | |

| 8 | 7 | 1.52 | 60 | 6.4 | 102 | 40 | 50 | 55 | |

| 6 | 7 | 1.52 | 60 | 7.3 | 151 | 55 | 65 | 75 | |

| 4 | 7 | 1.52 | 60 | 8.5 | 229 | 70 | 85 | 95 | |

| 2 | 7 | 1.52 | 60 | 9.9 | 349 | 95 | 115 | 130 | |

| 1 | 18 | 2.03 | 80 | 11.7 | 452 | 110 | 130 | 145 | |

| 1/0 | 18 | 2.03 | 80 | 12.6 | 559 | 125 | 150 | 170 | |

| 2/0 | 18 | 2.03 | 80 | 13.6 | 693 | 145 | 175 | 195 | |

| 3/0 | 18 | 2.03 | 80 | 14.8 | 861 | 165 | 200 | 225 | |

| 4/0 | 18 | 2.03 | 80 | 16.1 | 1069 | 195 | 230 | 260 | |

| 250 | 35 | 2.41 | 95 | 18.0 | 1282 | 215 | 255 | 290 | |

| 300 | 35 | 2.41 | 95 | 19.3 | 1519 | 240 | 285 | 320 | |

| 350 | 35 | 2.41 | 95 | 20.5 | 1756 | 260 | 310 | 350 | |

| 400 | 35 | 2.41 | 95 | 21.6 | 2001 | 280 | 335 | 380 | |

| 500 | 35 | 2.41 | 95 | 23.5 | 2470 | 320 | 380 | 430 | |

| 600 | 58 | 2.79 | 110 | 26.2 | 2983 | 350 | 420 | 475 | |

| 700 | 58 | 2.79 | 110 | 27.9 | 3461 | 385 | 460 | 520 | |

| 750 | 58 | 2.79 | 110 | 28.6 | 3695 | 400 | 475 | 535 | |

| 900 | 58 | 2.79 | 110 | 31.0 | 4407 | 435 | 520 | 585 | |

| 1000 | 58 | 2.79 | 110 | 32.5 | 4884 | 455 | 545 | 615 | |

+Allowable ampacities shown are for general use as specified by the 2014 Edition of the National Electrical Code Sections 310.15 and 240.4(D). Unless the equipment is marked for use at higher temperatures the conductor shall be limited to the following per NEC 110.14(C):

75℃ – When terminated to equipment for circuits rated over 100 amperes or marked for conductors larger than 1 AWG.

90℃ – THHN dry locations and THWN-2 wet or dry locations for ampacity adjustment purposes using NEC section 310.15.

YOU MAY LIKE

Related products

-

Building Wire

H05VV-F (RVV)

-

Building Wire

XHHW-2 COPPER CONDUCTOR

-

Building Wire

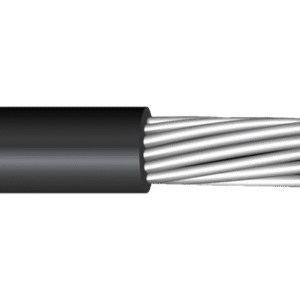

RHH/RHW-2/USE-2 ALUMINUM CONDUCTOR

-

Building Wire

XHHW-2 ALUMINUM CONDUCTOR

-

Building Wire

THWN or THHN

-

Building Wire

H07V-U – BV (Cu/PVC)

-

Building Wire

H07V-R (BVR)

-

Building Wire

H07V-K (RV)