Contact Wire (Cu-Ag/Cu-Sn/Cu-Mg Alloy)for Electrified Railway

The drawing stock or intermediate rod stock is a copper or copper silver as defined in standard EN 1977 or a copper cadmium, copper magnesium or copper tin alloy.

Application

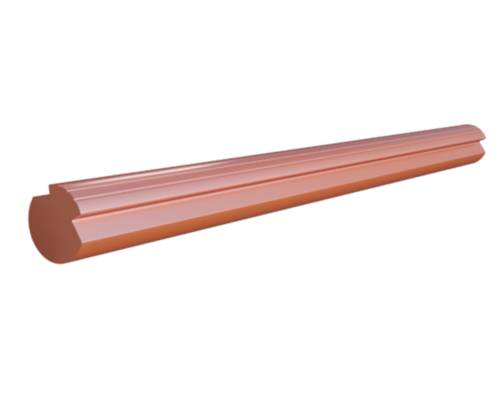

Contact wire is a electric conductor of an overhead contact line with which the current collector makes contact and is characterized by two clamping grooves. Copper and copper alloy grooved contact wires can be used in railway applications, Fixed installations and electric traction.

Description

The drawing stock or intermediate rod stock is a copper or copper silver as defined in standard EN 1977 or a copper cadmium, copper magnesium or copper tin alloy.

Note:

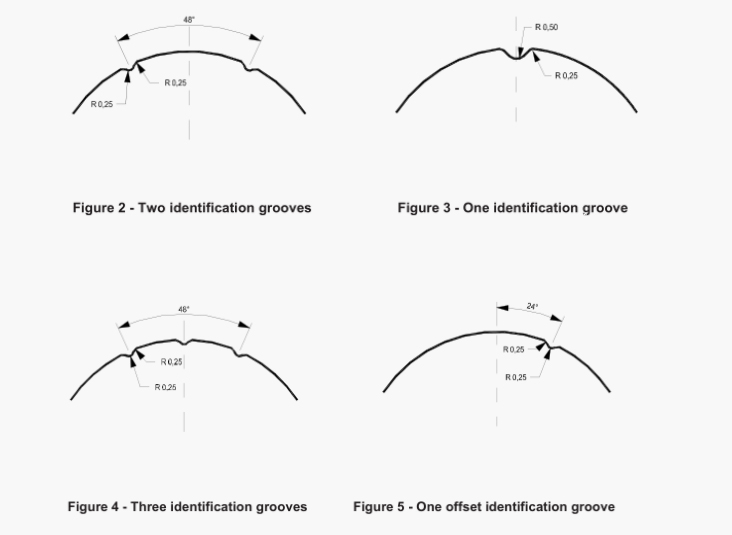

1)To identify the different copper(alloys) used as contact wire, identification grooves are used.

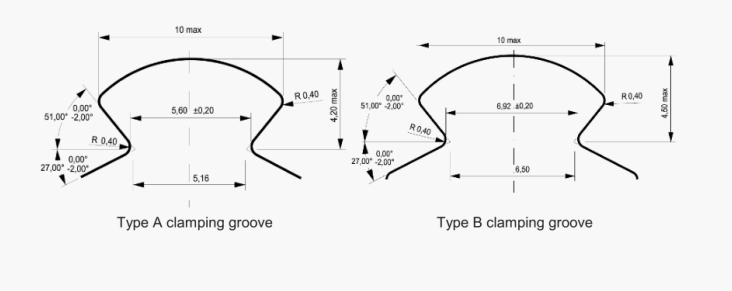

2)Whatever cross section of the wire is used, the dimensions of the clamping grooves shall be in accordance with standard.

Specification

● BS EN 50149 Railway Applications – Fixed Installations – Electric Traction -Copper And Copper Alloy

● Grooved Contact Wires

● TB/T 2809 Copper And Copper Alloy Contact Wires For Electric Railway

● ГOCT 2584 Провода контактные из меди и ее сплавов. Технические условия

Technical Parameter

| Material | Nominal Cross Section | Designation | Max. resistance at 20 °C | Min. Breaking Load | Mass | Percentage elongation after Fracture A200 | Min. Tensile Strength | ||

| mm² | Ω/km | kN | Min. kg/km | Max. kg/km | Min. % | Max. % | N/mm² | ||

| Normal Strength Copper | 80 | Cu-ETP Cu-FRHC Cu-HCP Cu-OF | 0.229 | 27.5 | 690 | 733 | 3 | 10 | 355 |

| 100 | 0.183 | 34.5 | 862 | 916 | 3 | 10 | 355 | ||

| 107 | 0.171 | 36.3 | 923 | 980 | 3 | 10 | 350 | ||

| 120 | 0.153 | 38.4 | 1035 | 1099 | 3 | 10 | 330 | ||

| 150 | 0.122 | 45.1 | 1293 | 1374 | 3 | 10 | 310 | ||

| High strength Copper and high strength Copper-silver Alloy | 80 | Cu-ETP Cu-FRHC Cu-HCP Cu-OF Cu-Ag 0.1 | 0.229 | 29.1 | 690 | 733 | 3 | 8 | 375 |

| 100 | 0.183 | 36.4 | 862 | 916 | 3 | 8 | 375 | ||

| 107 | 0.171 | 37.4 | 923 | 980 | 3 | 8 | 360 | ||

| 120 | 0.153 | 41.9 | 1035 | 1099 | 3 | 8 | 360 | ||

| 150 | 0.122 | 52.2 | 1293 | 1374 | 3 | 8 | 360 | ||

| Normal Strength Copper-silver Alloy | 80 | Cu-Ag 0.1 | 0.229 | 28.3 | 690 | 733 | 3 | 10 | 365 |

| 100 | 0.183 | 34.9 | 862 | 916 | 3 | 10 | 360 | ||

| 107 | 0.171 | 36.3 | 923 | 980 | 3 | 10 | 350 | ||

| 120 | 0.153 | 40.7 | 1035 | 1099 | 3 | 10 | 350 | ||

| 150 | 0.122 | 50.9 | 1293 | 1374 | 3 | 10 | 350 | ||

| Copper-magnesium alloy | 80 | Cu-Mg 0.2 | 0.289 | 35.7 | 690 | 733 | 3 | 10 | 460 |

| 100 | 0.231 | 43.7 | 862 | 916 | 3 | 10 | 450 | ||

| 107 | 0.216 | 45.7 | 923 | 980 | 3 | 10 | 440 | ||

| 120 | 0.192 | 50.1 | 1035 | 1099 | 3 | 10 | 430 | ||

| 150 | 0.154 | 61.1 | 1293 | 1374 | 3 | 10 | 420 | ||

| Copper-magnesium alloy | 80 | Cu-Mg 0.5 | 0.385 | 40.4 | 690 | 733 | 3 | 10 | 520 |

| 100 | 0.286 | 49.5 | 862 | 916 | 3 | 10 | 510 | ||

| 107 | 0.268 | 51.9 | 923 | 980 | 3 | 10 | 500 | ||

| 120 | 0.239 | 57.0 | 1035 | 1099 | 3 | 10 | 490 | ||

| 150 | 0.191 | 68.4 | 1293 | 1374 | 3 | 10 | 470 | ||

Copper and Copper Alloy Grooved Contact wires

| Material | Nominal Cross Section | Designation | Max. resistance at 20 °C | Min. Breaking Load | Mass | Percentage elongation after Fracture A200 | Min. Tensile Strength | ||

| mm² | Ω/km | kN | Min. kg/km | Max. kg/km | Min. % | Max. % | N/mm² | ||

| Copper-tin alloy | 80 | Cu-Sn 0.2 | 0.309 | 35.7 | 692 | 735 | 2 | 8 | 460 |

| 100 | 0.247 | 43.7 | 865 | 919 | 2 | 8 | 450 | ||

| 107 | 0.231 | 44.6 | 926 | 983 | 2 | 8 | 430 | ||

| 120 | 0.206 | 48.9 | 1038 | 1103 | 2 | 8 | 420 | ||

| 150 | 0.165 | 61.1 | 1298 | 1378 | 2 | 8 | 420 | ||

| Copper-cadmium alloy | 80 | Cu-Cd 0.7 | 0.258 | 33.4 | 694 | 737 | 2 | 7 | 430 |

| 100 | 0.207 | 41.7 | 868 | 921 | 2 | 7 | 430 | ||

| 107 | 0.193 | 44.6 | 928 | 986 | 2 | 7 | 430 | ||

| 120 | 0.172 | 50.1 | 1041 | 1106 | 2 | 7 | 430 | ||

| 150 | 0.138 | 62.6 | 1301 | 1382 | 2 | 7 | 430 | ||

| Copper-cadmium alloy | 80 | Cu-Cd 1.0 | 0.278 | 35.3 | 694 | 737 | 2 | 7 | 455 |

| 100 | 0.222 | 43.2 | 868 | 921 | 2 | 7 | 445 | ||

| 107 | 0.208 | 46.2 | 928 | 986 | 2 | 7 | 445 | ||

| 120 | 0.185 | 51.8 | 1041 | 1106 | 2 | 7 | 445 | ||

| 150 | 0.148 | 64.7 | 1301 | 1382 | 2 | 7 | 445 | ||

| Note: The detailed size of the product shall be in accordance with standard. | |||||||||

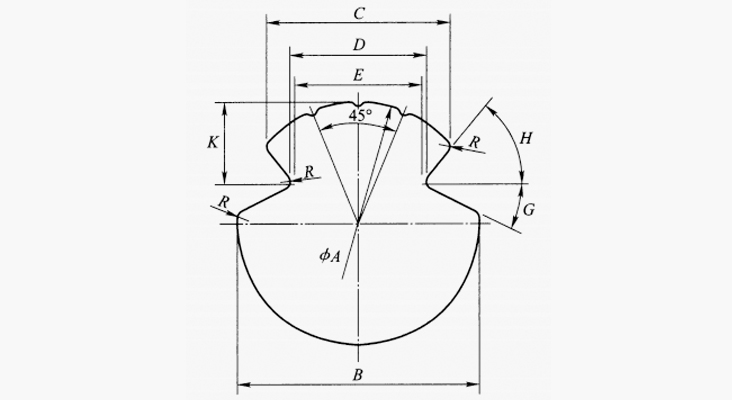

1) Identification grooves

2) Clamping grooves

| Nominal cross section | Calculated cross section | Size and tolerance mm | Angle and tolerance | |||||||||||

| mm² | mm² | A | B | C | D | E | K | R | G | H | ||||

| 120 | 121 | 12.90 | +0.13 | 12.90 | +0.26 | 9.76 | +0.20 | 7.24 | +0.29 | 6.80 | 4.35 | 0.40 | 27°±1° | 51°±1° |

| -0.13 | -0.26 | -0.20 | -0.14 | |||||||||||

| 150 | 151 | 14.40 | +0.14 | 14.40 | +0.29 | 9.71 | +0.19 | 7.24 | +0.29 | 6.80 | 4.00 | 0.40 | 27°±1° | 51°±1° |

| -0.14 | -0.29 | -0.19 | -0.14 | |||||||||||

Note:

| ||||||||||||||

| Type | Tensile streng th MPa | Softening fraction | Elongation (unsoftened) | Repeated bending | Number of turns (until disconnected) | Number of turns | Conductivity(20 °C)% IACS | Resistivity (20°C) Ω · mm2/m | Temperature coefficient of resistance | |

| Crack | Disconnect | |||||||||

| CT | ≥360 | – | ≥3.0% | ≥4 | ≥6 | ≥5 | ≥3 | ≥97 | ≤0.01777 | 0.00380 |

| CTA | ≥370 | ≥90% | ≥3.0% | ≥4 | ≥6 | ≥5 | ≥3 | ≥97 | ≤0.01777 | 0.00380 |

| CTS | ≥380 | ≥90% | ≥3.0% | ≥4 | ≥6 | ≥5 | ≥3 | ≥93 | ≤0.01854 | 0.00320 |

| CTSM | ≥430 | ≥90% | ≥3.0% | ≥4 | ≥6 | ≥5 | ≥3 | ≥80 | ≤0.02155 | 0.00320 |

| CTM | 0.00310 | |||||||||

| CTSH | ≥500 | ≥90% | ≥3.0% | ≥4 | ≥6 | ≥5 | ≥3 | ≥68 | ≤0.02535 | 0.00320 |

| CTMM | 0.00270 | |||||||||

| CTMH | ≥530 | ≥90% | ≥3.0% | ≥4 | ≥6 | ≥5 | ≥3 | ≥65 | ≤0.02653 | 0.00270 |

| CTCZ | ≥560 | ≥95% | ≥3.0% | ≥4 | ≥6 | ≥5 | ≥3 | ≥75 | ≤0.02299 | 0.00320 |

YOU MAY LIKE

Related products

-

Contact and Catenary Wire for Railway

Catenary Wire (Copper alloy Stranded)for Electrified Railway