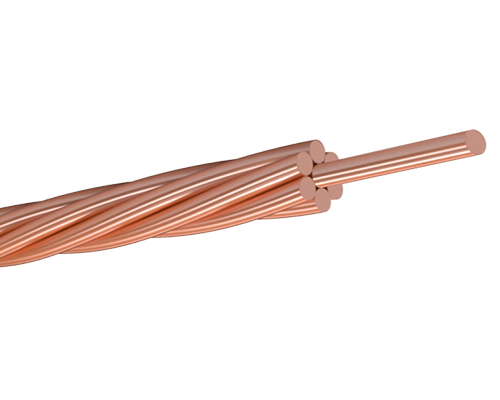

Catenary Wire (Copper alloy Stranded)for Electrified Railway

Conductor is concentrically stranded with bare copper or copper alloy wire.

Application

Stranded bare copper and copper alloy are suitable for overhead power transmission systems and overhead electric traction systems.

Description

Conductor is concentrically stranded with bare copper or copper alloy wire.

Specification

● ASTM B 8 Concentric-Lay-Stranded Copper Conductors, Hard, Medium-Hard, or Soft

● BS 7884 Copper And Copper – Cadmium Stranded Conductors For Overhead Electric Traction And Power Transmission Systems

● DIN 48201-1 Seile aus kupfer

● TB/T 3111 Copper And Copper Alloy Stranded Conductors for Electric Railway

Stranded bare copper and copper alloy are suitable for overhead power transmission systems and overhead electric traction systems.

Description

Conductor is concentrically stranded with bare copper or copper alloy wire.

Specification

● ASTM B 8 Concentric-Lay-Stranded Copper Conductors, Hard, Medium-Hard, or Soft

● BS 7884 Copper And Copper – Cadmium Stranded Conductors For Overhead Electric Traction And Power Transmission Systems

● DIN 48201-1 Seile aus kupfer

● TB/T 3111 Copper And Copper Alloy Stranded Conductors for Electric Railway

Technical Parameter

Hard Drawn Copper Stranded Conductors

| Nominal area of cross-section of stranded conductor | Construction (stranding and wire diameter) | Overall diameter of conductor (approx.) | Nominal mass per unit length | Resistance at 20 °C | Minimum breaking load | |

| Nominal | Max. | |||||

| mm² | number/mm | mm | kg/km | Ω/km | Ω/km | N |

| 10 | 7/1.35 | 4.05 | 89.82 | 1.788 | 1.829 | 3752 |

| 14 | 7/1.60 | 4.80 | 126.2 | 1.273 | 1.303 | 5267 |

| 16 | 3/2.65 | 5.70 | 148.3 | 1.082 | 1.106 | 6194 |

| 16 | 7/1.70 | 5.10 | 142.4 | 1.128 | 1.154 | 5946 |

| 25 | 7/2.10 | 6.30 | 217.3 | 0.7391 | 0.7563 | 9073 |

| 32 | 3/3.75 | 8.06 | 296.9 | 0.5405 | 0.5520 | 12400 |

| 32 | 7/2.46 | 7.38 | 298.2 | 0.5386 | 0.5497 | 12442 |

| 35 | 7/2.50 | 7.50 | 308.0 | 0.5215 | 0.5337 | 12860 |

| 50 | 7/3.00 | 9.00 | 443.5 | 0.3622 | 0.3706 | 18520 |

| 50 | 19/1.80 | 9.00 | 435.8 | 0.3727 | 0.3819 | 17700 |

| 70 | 7/3.55 | 10.65 | 621.1 | 0.2586 | 0.2646 | 25930 |

| 70 | 19/2.10 | 10.50 | 593.2 | 0.2738 | 0.2806 | 24090 |

| 95 | 19/2.50 | 12.50 | 840.7 | 0.1932 | 0.1980 | 34140 |

| 100 | 7/4.30 | 12.90 | 911.2 | 0.1763 | 0.1810 | 36540 |

| 120 | 19/2.80 | 14.00 | 1055 | 0.1540 | 0.1578 | 42830 |

| 125 | 19/2.90 | 14.50 | 1131 | 0.1436 | 0.1471 | 45940 |

| 150 | 19/3.20 | 16.00 | 1377 | 0.1180 | 0.1208 | 55940 |

| 150 | 37/2.25 | 15.75 | 1334 | 0.1233 | 0.1264 | 53880 |

| 185 | 19/3.55 | 17.75 | 1695 | 0.09582 | 0.09815 | 68860 |

| 185 | 37/2.50 | 17.50 | 1647 | 0.09981 | 0.1024 | 66490 |

Hard Drawn Copper Stranded Conductors

| Nominal area of cross-section of stranded conductor | Construction (stranding and wire diameter) | Overall diameter of conductor (approx.) | Nominal mass per unit length | Resistance at 20 °C | Minimum breaking load | |

| Nominal | Max. | |||||

| mm² | number/mm | mm | kg/km | Ω/km | Ω/km | N |

| 12 | 3/2.30 | 4.95 | 112.4 | 1.743 | 1.780 | 6968 |

| 16 | 7/1.70 | 5.10 | 143.3 | 1.368 | 1.399 | 8883 |

| 22 | 7/2.00 | 6.00 | 198.3 | 0.9882 | 1.011 | 12290 |

| 25 | 7/2.10 | 6.30 | 218.7 | 0.8959 | 0.9171 | 13550 |

| 30 | 7/2.30 | 6.90 | 262.3 | 0.7469 | 0.7645 | 16260 |

| 35 | 7/2.50 | 7.50 | 309.9 | 0.6324 | 0.6471 | 19210 |

| 38 | 7/2.60 | 7.80 | 335.2 | 0.5847 | 0.5983 | 20780 |

| 45 | 7/2.90 | 8.70 | 417.0 | 0.4698 | 0.4809 | 24600 |

| 55 | 7/3.20 | 9.60 | 507.8 | 0.3859 | 0.3950 | 29950 |

| 70 | 19/2.10 | 10.50 | 596.8 | 0.3316 | 0.3403 | 35990 |

| 75 | 7/3.70 | 11.10 | 678.8 | 0.2887 | 0.2954 | 38010 |

| 95 | 19/2.50 | 12.50 | 845.9 | 0.2343 | 0.2400 | 51010 |

| 100 | 7/4.30 | 12.90 | 916.9 | 0.2138 | 0.2195 | 51160 |

| 120 | 19/2.80 | 14.00 | 1061 | 0.1862 | 0.1914 | 60890 |

| 125 | 19/2.90 | 14.50 | 1138 | 0.1739 | 0.1784 | 65310 |

| 150 | 19/3.20 | 16.00 | 1386 | 0.1428 | 0.1465 | 79530 |

| 150 | 37/2.25 | 15.75 | 1342 | 0.1493 | 0.1533 | 80490 |

| 180 | 19/3.50 | 17.50 | 1658 | 0.1196 | 0.1225 | 95140 |

| 180 | 37/2.50 | 17.50 | 1657 | 0.1209 | 0.1242 | 99330 |

| 200 | 19/3.70 | 18.50 | 1853 | 0.1068 | 0.1696 | 100900 |

| 240 | 19/4.00 | 20.00 | 2165 | 0.09153 | 0.09378 | 117900 |

Copper Stranded Wire

| Nominal area mm² | Cross- sectional area mm² | Wire | Overall diameter mm | Approx. mass per unit length kg/km | Rated strength kN | Current carrying capacity A | |

| Number | Diameter mm | ||||||

| 10 | 10.02 | 7 | 1.35 | 4.1 | 90 | 4.02 | 90 |

| 16 | 15.89 | 7 | 1.70 | 5.1 | 143 | 6.37 | 125 |

| 25 | 24.25 | 7 | 2.10 | 6.3 | 218 | 9.72 | 160 |

| 35 | 34.36 | 7 | 2.50 | 7.5 | 310 | 13.77 | 200 |

| 50 | 49.48 | 7 | 3.00 | 9.0 | 446 | 19.84 | 250 |

| 48.35 | 19 | 1.80 | 9.0 | 437 | 19.38 | 250 | |

| 70 | 65.81 | 19 | 2.10 | 10.5 | 596 | 26.38 | 310 |

| 95 | 93.27 | 19 | 2.50 | 12.5 | 845 | 37.39 | 380 |

| 120 | 116.99 | 19 | 2.80 | 14.0 | 1060 | 46.90 | 440 |

| 150 | 147.11 | 37 | 2.25 | 15.8 | 1337 | 58.98 | 510 |

| 185 | 181.62 | 37 | 2.50 | 17.5 | 1649 | 72.81 | 585 |

| 240 | 242.54 | 61 | 2.25 | 20.3 | 2209 | 97.23 | 700 |

| 300 | 299.43 | 61 | 2.50 | 22.5 | 2725 | 120.04 | 800 |

| 400 | 400.14 | 61 | 2.89 | 26.0 | 3640 | 160.42 | 960 |

| 500 | 499.83 | 61 | 3.23 | 29.1 | 4545 | 200.38 | 1110 |

| Note: Current carrying capacity are valid up to a frequency of 60 Hz,a wind velocity of 0.6 m/s, an initial ambient temperature of 35 °C and a conductor temperature of 70°C. | |||||||

Copper and Copper Alloy Stranded Wire

| Type | Section area mm² | Calculated overall diameter mm | Structure | Single wire diameter mm | Single wire | Stranded wire (Nominal) | ||||

| Min. tensile strength MPa | Min. elongation % | Min. breaking load kN | Mass per unit length kg/km | |||||||

| Nominal | Cross- sectional | Before stranding | After stranding | |||||||

| JT | 70 | 65.81 | 10.50 | 1×19 | 2.10 | 430 | 410 | 0.7 | 27.45 | 596 |

| JT | 95 | 93.27 | 12.50 | 1×19 | 2.50 | 430 | 410 | 0.7 | 38.54 | 844 |

| JT | 120 | 116.99 | 14.00 | 1×19 | 2.80 | 430 | 410 | 0.7 | 48.01 | 1059 |

| JT | 150 | 147.12 | 15.75 | 1×37 | 2.25 | 430 | 410 | 0.7 | 61.21 | 1334 |

| JTM | 25 | 24.25 | 6.30 | 1×7 | 2.10 | 520 | 494 | — | 11.98 | 218 |

| JTM | 35 | 34.36 | 7.50 | 1×7 | 2.50 | 520 | 494 | — | 16.97 | 309 |

| JTM | 35 | 34.93 | 7.65 | 1×19 | 1.53 | 520 | 494 | — | 17.26 | 316 |

| JTM | 50 | 49.48 | 9.00 | 1×7 | 3.00 | 520 | 494 | — | 24.44 | 446 |

| JTM | 50 | 48.35 | 9.00 | 1×19 | 1.80 | 520 | 494 | — | 23.88 | 438 |

| JTM | 70 | 65.81 | 10.50 | 1×19 | 2.10 | 520 | 494 | — | 32.51 | 596 |

| JTM | 95 | 93.27 | 12.50 | 1×19 | 2.50 | 520 | 494 | — | 46.08 | 844 |

| JTM | 120 | 116.99 | 14.00 | 1×19 | 2.80 | 520 | 494 | — | 57.79 | 1059 |

| JTM | 150 | 147.12 | 15.75 | 1×37 | 2.25 | 520 | 494 | — | 72.67 | 1334 |

| JTMH | 25 | 24.25 | 6.30 | 1×7 | 2.10 | 620 | 589 | — | 14.28 | 218 |

| JTMH | 35 | 34.36 | 7.50 | 1×7 | 2.50 | 620 | 589 | — | 20.24 | 309 |

| JTMH | 35 | 34.93 | 7.65 | 1×19 | 1.53 | 620 | 589 | — | 20.57 | 316 |

| JTMH | 50 | 49.48 | 9.00 | 1×7 | 3.00 | 620 | 589 | — | 29.14 | 446 |

| JTMH | 50 | 48.35 | 9.00 | 1×19 | 1.80 | 620 | 589 | — | 28.48 | 438 |

| JTMH | 70 | 65.81 | 10.50 | 1×19 | 2.10 | 620 | 589 | — | 38.76 | 596 |

| JTMH | 95 | 93.27 | 12.50 | 1×19 | 2.50 | 620 | 589 | — | 54.94 | 844 |

| JTMH | 120 | 116.99 | 14.00 | 1×19 | 2.80 | 620 | 589 | — | 68.91 | 1059 |

| JTMH | 150 | 147.11 | 15.75 | 1×37 | 2.25 | 620 | 589 | — | 86.65 | 1334 |

| JTMM | 70 | 65.81 | 10.50 | 1×19 | 2.10 | 620 | 589 | — | 38.76 | 596 |

| JTMM | 95 | 93.27 | 12.50 | 1×19 | 2.50 | 620 | 589 | — | 54.94 | 844 |

| JTMM | 120 | 116.99 | 14.00 | 1×19 | 2.80 | 620 | 589 | — | 68.91 | 1059 |

| JTMM | 150 | 147.11 | 15.75 | 1×37 | 2.25 | 620 | 589 | — | 86.65 | 1334 |

| JTCZ120 | 120 | 119.75 | 14.21 | 1×37 | 2.03 | 520 | 494 | — | 59.16 | 1092 |

YOU MAY LIKE

Related products

-

Contact and Catenary Wire for Railway

Contact Wire (Cu-Ag/Cu-Sn/Cu-Mg Alloy)for Electrified Railway